Flat-bottom steeps and

cylindroconical steep tanks

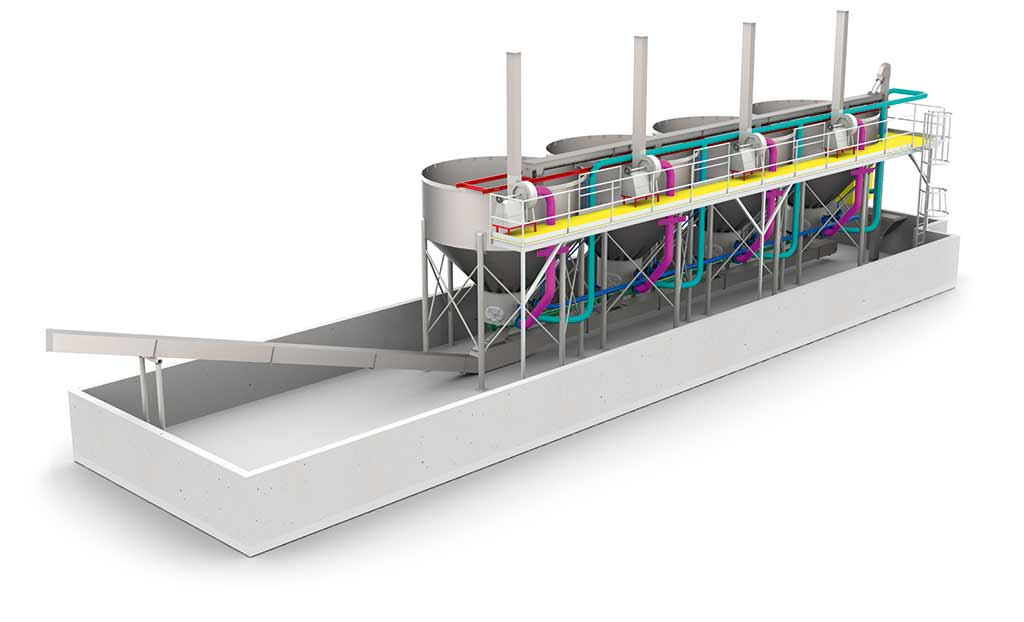

Rauscher engineering is one of the biggest engineering offices for layout, design, manufacture and installation of entire state-of-the-art steeping plants worldwide.

Flat-bottom steeps and

cylindroconical steep tanks

cylindroconical steep tanks

Flat-bottom steeps

State-of-the-art flat-bottom steeps comprise the following:- Stainless steel design steep vessels

- Pressure aeration with rotary-piston blower

- CO2-suction with ventilator/fan

- Radial remover for automatic loading and unloading

- Rotating machine with liftable loading and unloading screw

- Complete piping with valves for supply and waste water as well as aeration, CO2-suction and cleaning system

- Adjustable overflow system for floating barley

- Mesh floor with unloading system and possibility for cleaning

- CIP system for steep vessel

- Steel construction for steeping plant

Cylindroconical steeps

State-of-the-art cylindroconical steeps comprise the following:- Stainless steel design steep vessels

- Pressure aeration with rotary-piston blower

- CO2-suction with ventilator/fan

- Steep bowl with pipe connections and access opening for easy cleaning

- Central tube (circulating tube) for washing, aerating and mixing steeped barley

- Complete piping with valves for supply and waste water as well as aeration, CO2-suction and cleaning system

- Adjustable overflow system for floating barley

- CIP system for steep tanks

- Support structure for steep tanks

- Steel construction for steep tanks

Pre-steeping

Pre-steeping

- Pre-steeping - for cleaning and pre-steeping barley and other cereals

- Slurry tanks - for mixing barley and water and for pumping into the steep vessels

Product handling

images